Annotated pictures are a great visual communication tool to show contractors exactly what needs to be done. When combined with 3D scanning and modelling, there is no room left for confusion as they can see the changes needed in a photorealistic augmentation of photography and 3D Design.

Read more →A 3D model of the process system and facility provides a foundation for generating layout, elevation and orthographic views of the process. Isometric piping drawings with bill-of-material can be generated to significantly reduce construction costs and change orders. Three-dimensional models are used for a virtual walk-through to

Read more →Generated from the 3D model, our isometric drawings highlight each pipe run one at a time. The dimensions and end point labels aid in accurate budget quotes from the piping contractor and provide increased clarity to the installer, reducing pipe fitting time.

Read more →4D planning allows simulation of demolition and construction activities to eliminate delays and sequencing problems. State-of-the-art software provides a dynamic link between the project model and the project management software. Using the fourth dimension of time in conjunction with the 3D model, conflicts can be discovered and

Read more →Laying out the equipment in a process is one of the most important aspects of the design process. Proper layout considers ergonomics and efficient material flow while keeping it accessible for cleaning.

Read more →Equipment lists detail all major equipment in a project including part numbers, description, size, manufacturer, supplier and quantity. This can also include device numbers for programming.

Read more →Good Piping and Instrumentation Diagrams are the foundation of good process design, but most P&IDs are hard to read, cumbersome to work with, and lack critical details. Our P&IDs are clean, printed to convenient sizes so you can carry them around the plant, and clearly state all

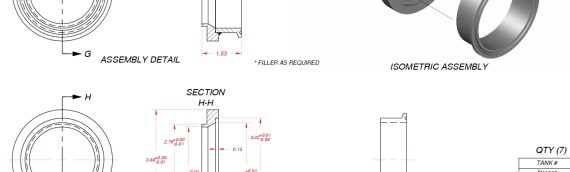

Read more →Ranging from pipe hangers to pump base designs, the detail drawings allow fabricators and contractors to build exactly what the owner is expecting because of a pre-approved detail drawing.

Read more →CIP systems in today’s food industry still range from non-existent to state-of-the-art. Whatever their current position in the cleaning evolution, we move the food producer forward to optimize their cleaning. Common Deliverables Designs from basic to highly-automated state-of-the-art CIP system CIP pin charts CIP sequence of operations

Read more →CIP design goes hand-in-hand with the process design. Using innovative equipment and instrumentation, CIP system designs greatly reduce production downtime and meet important criteria such as water and energy reduction. A Central CIP System delivers the right solutions at the proper flow rate, temperature and chemical concentration

Read more →