process design

Process design in food manufacturing uses many universal process operations such as fluid flow, heat transfer, mixing, separation and chemical reaction. With a solid foundation in science, math and engineering, we provide innovative solutions to improve quality, safety and operational efficiency. Applying our years of practical experience in the food industry, we create solid designs to meet the goals of the business. Process design might be a greenfield project, working within a large, multi-discipline design team or may be focused on improving an existing process. Minimizing production downtime is often a consideration of the food process design for those with tight construction schedules and vertical start-ups.

Expertise in sanitary process design is fundamental to the foundation of Cook Process Solutions. Food processes require special attention in piping design which can be CIP cleaned and fully drainable. Steve Cook’s early years as a sanitary pipe fitter taught him the intricate details of properly routing pipe with slope for drainage and easy swing connections. He also saw the results when piping systems weren’t properly designed. From his education in mechanical engineering to his field experience as a pipe fitter in the food industry, Steve Cook has a level of expertise and perspective that’s rarely found in food process engineers.

3-A Sanitary Standards as well as EHEDG and applicable food industry regulations are all and important basis for the design work. Systems that produce safe food products start with hygienic designs.

- site survey

- process development

- mass and energy balance

- heat transfer

- fluid flow analysis

- piping design

- mixproof valve application

- control valve sizing

- heat exchanger selection

- pump selection

- 3D modeling

- simulation

- equipment layout

- ergonomics

- equipment modifications

- bid packages

- scope documents

- CIP pin Charts

- equipment lists

Drawings

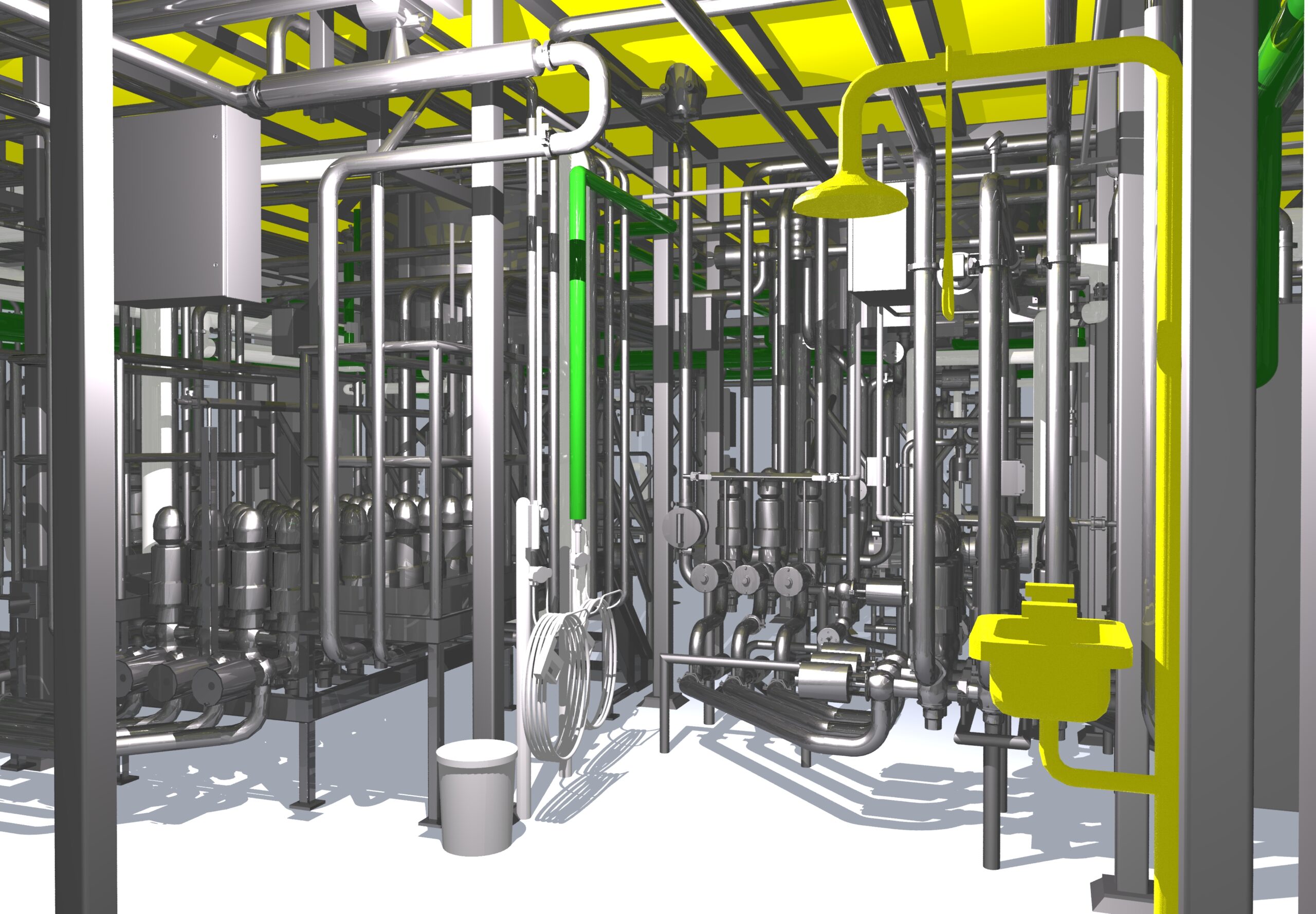

Various types of drawings are used throughout the design process everything from conceptual development employing block diagrams to life-like 3Dmodels of entire process facilities. Cook Process Solutions uses high performance work stations and state-of-the-art software to deliver drawings meeting strict quality standards with cutting-edge 3D models.

We create clear and concise drawings using specialized industry-specific symbols and standards. Strict drawing control methods ensure that only the latest drawings are available to the project team.

Common drawings produced in our projects:

- block diagrams

- PFD – process flow diagrams

- P&ID – process and instrumentation diagrams

- 3D models

- piping isometrics

- orthographics

- detail sheets

- fabrication drawings elevations

- equipment layout

Deliverables

Other DeliverabLES

- Specialties: Food process design

- Sanitary system design

- Sanitary equipment design

- CIP design

- Fluid dynamics modeling

- Mix proof valve application

- System optimization

- Fluids modeling

- Energy/Mass Balance

- Trouble shooting

- Pasteurization design

- CIP improvements and implementation

- Testing and Trials

- Equipment evaluations

- Expansion planning

- Conceptual and detailed design

- Process flow diagrams

- Process and Instrumentation drawings

- Root Cause analysis

- Budget planning

- Master Planning

- Rheology application to process

- Animal Food process upgrades

- FSMA