Process design in food manufacturing uses many universal process operations such as fluid flow, heat transfer, mixing, separation and chemical reaction. With a solid foundation in science, math and engineering, we provide innovative solutions to improve quality, safety and operational efficiency. Read more…

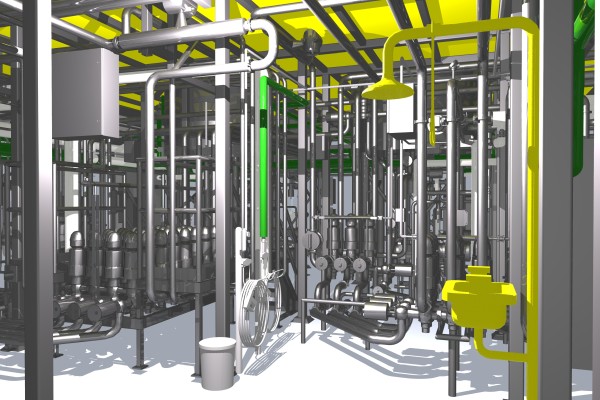

A 3D model of the process system and facility provides a realistic design that improves the design process from inception to commissioning. Three-dimensional models are used for a virtual walk-through to gather valuable design feedback from safety, maintenance, operations, and quality personnel. Read more…

Understanding the desired outcome is the first step to successful consulting. We actively discover your goals and their importance to your business. Then, our years of experience working with food processes gives us a unique perspective to find solutions for your most complicated process and CIP challenges. Read more…

Deliverables

Other Deliverables

- Specialties: Food process design

- Sanitary system design

- Sanitary equipment design

- CIP design

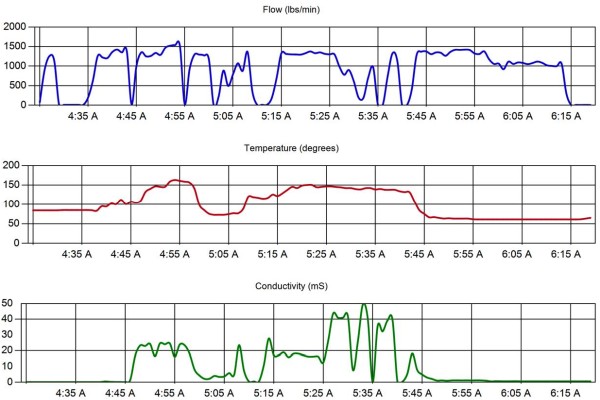

- Fluid dynamics modeling

- Mix proof valve application

- System optimization

- Fluids modeling

- Energy/Mass Balance

- Trouble shooting

- Pasteurization design

- CIP improvements and implementation

- Testing and Trials

- Equipment evaluations

- Expansion planning

- Conceptual and detailed design

- Process flow diagrams

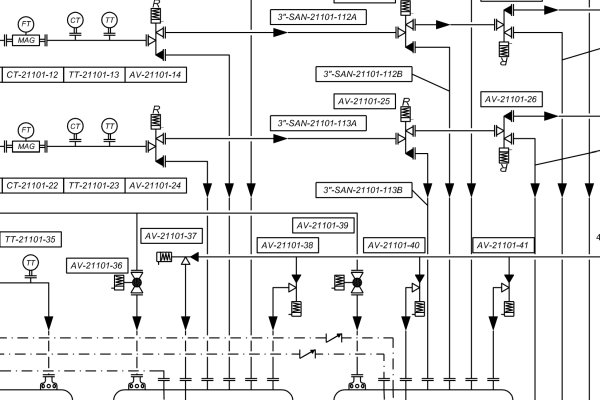

- Process and Instrumentation drawings

- Root Cause analysis

- Budget planning

- Master Planning

- Rheology application to process

- Animal Food process upgrades

- FSMA